Cryogenic multistream heat exchangers and associated

heat exchanger networks

Design framework for multistream compact heat exchangers and associated networks

The design of MCHE and associated HEN should be a process that can comprehensively analyze the relevant issues at different levels. At the system level, the designers should determine the configuration of HEN, i.e., how to organize the streams to satisfy all the heat transfer duties, which stream enters or leaves at what position and what are the pressure drop for each stream, the log mean temperature difference of the exchanger and the Pinch point temperature of the system. At the heat exchanger level, decisions need to be made on the quantity of layers for each stream, fin selection for each layer, the layer pattern for all streams and the size of heat exchangers. There are strong interactions between these two different levels, which should be treated as an overall framework but not isolated from each other. However, most of the previous research works only paid attention to a single aspect by ignoring the interactions between them, not to mention presenting optimization framework that combines the thermo-hydraulic MCHE model with the HEN design.

This study develops a novel overall optimization framework with a three-tier structure: the superstructure expresses the multi-stream organization matching based on Pinch analysis on HEN, the middle structure is the fin selection design and layer pattern using thermo-hydraulic modeling and multi-objective optimization, and the kernel structure represents the simulation optimization with field synergy analysis. To improve the comprehensive performance of the designs, this optimization framework also carries out a tradeoff analysis on the pressure drop, heat transfer efficiency and other related parameters.

Layer assignment and arrangement of multi-passage heat transfer

The layer pattern problem has proved difficult to solve because the many types of hot and cold fluids involved in the heat exchange lead to combinatorial explosion. It is impractical for a designer to analyze all permutations exhaustively. Moreover, the nonuniformity of the temperature field and the pressure field between the layers are coupled to each other, making it difficult to derive a theoretical general solution formula to design the layer pattern. In fact, designing the layer pattern of an MPFHE is an integer nonlinear optimization problem, and the conventional continuous variable optimization method cannot be employed. To optimize of noncontinuous variables, it is necessary to perform numerous different layer pattern simulations. However, the number of simulations required to obtain optimized results increases with the number of layers.

The traditional gradient-based optimization method is also not effective because direct contact cannot be established between different layer patterns and random layers. This produces the nonuniform distribution phenomenon, making it impossible to avoid local optimal solution trap in the optimization process. Thus far, the layer pattern problem the key difficulty to overcome in the design and optimization of an MPFHE.

A novel layer assignment and arrangement modeling and optimization method is proposed in the present research to simultaneously consider these two problems. This method employs a combination of the equipartition of entropy production and the balance of local heat load, by means of which the pressure drop rises and heat transfer performance drop caused by inappropriate surface selection and layer pattern could be reduced to a large extent. The optimization model of the corresponding layer arrangement ring, which represents the hot and cold layer patterns, is extended to the temperature difference and pressure drop. The specific entropy generation rates of heat transfer and fluid friction are adopted as the dual-objective functions and simultaneously minimized. Considering that the layer arrangement ring is a binary string, the genetic algorithm hybrid with cuckoo search algorithm is used for the optimization. This combined method provides a good robustness and high efficiency for the surface selection and layer pattern optimization of main heat exchanger in air separation plants, which is a beneficial approach for the design of MPFHEs.

Experimental investigation of layer pattern design based on genetic algorithm

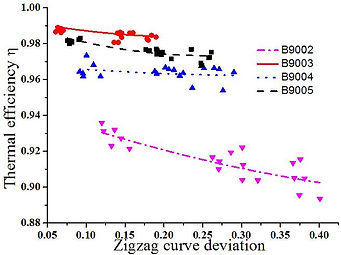

The experimental design included 4 heat exchanger configurations, which are listed as B9002-B9005. The dimensions, location of measurement points, type of fin, and guide plate are the same for the heat exchangers. They only are different in the layer pattern. The layer pattern, B9002 is designed for testing on trial and error basis in the experiments; B9003 is an optimization result from the local thermal equilibrium criteria genetic algorithm; B9004 and B9005 are the results of equal temperature difference criterion and equal NTU criterion, respectively.

With increasing zigzag curve deviation, the heat exchanger layer pattern efficiency decreased gradually. This trend in results establishes once again that is a key parameter in the heat exchanger layer pattern. The parameters and have a non-strictly decreasing relationship. Furthermore, the thermal efficiencies of the four heat exchangers with different layer patterns placed in decreasing order are B9003>B9005>B9004>B9002. These efficiencies of the four heat exchangers with different layer patterns confirm the efficacy of genetic algorithm optimization model and the accuracy of the conclusions. The scope of the heat transfer conditions of the different layer patterns studied can be further expanded to more extensive layer patterns and heat transfer situations.

With increasing zigzag curve deviation, the friction factor increased. The friction factors of the four heat exchangers with different layer patterns placed in increasing order are B9003<B9005<B9004<B9002. The performance of B9003 with respect to heat transfer and flow is the best among the four layers arranged heat exchangers, which clearly establishes the validity of the genetic algorithm optimization model used in the study. It is worth mentioning that the flow resistance of the MPFHE has a strong relationship with the layers pattern, fluid distribution, and header structure.